our approach aimed at maximizing productivity & efficiency.

Managing Director

CNC Machining, Built for the Real World

Kristek Precision offers a full suite of CNC machining services designed to meet your production requirements. Whether you require complex aerospace components or low-volume batch work, we deliver the accuracy, repeatability, and reliability essential in today’s demanding markets.

CNC Milling

We specialize in multi-axis CNC milling of complex parts, tight tolerances, and intricate geometries. Using the latest machining centres and CAD/CAM technology, we handle a wide range of materials—including aluminium, stainless steel, titanium, and engineering plastics.

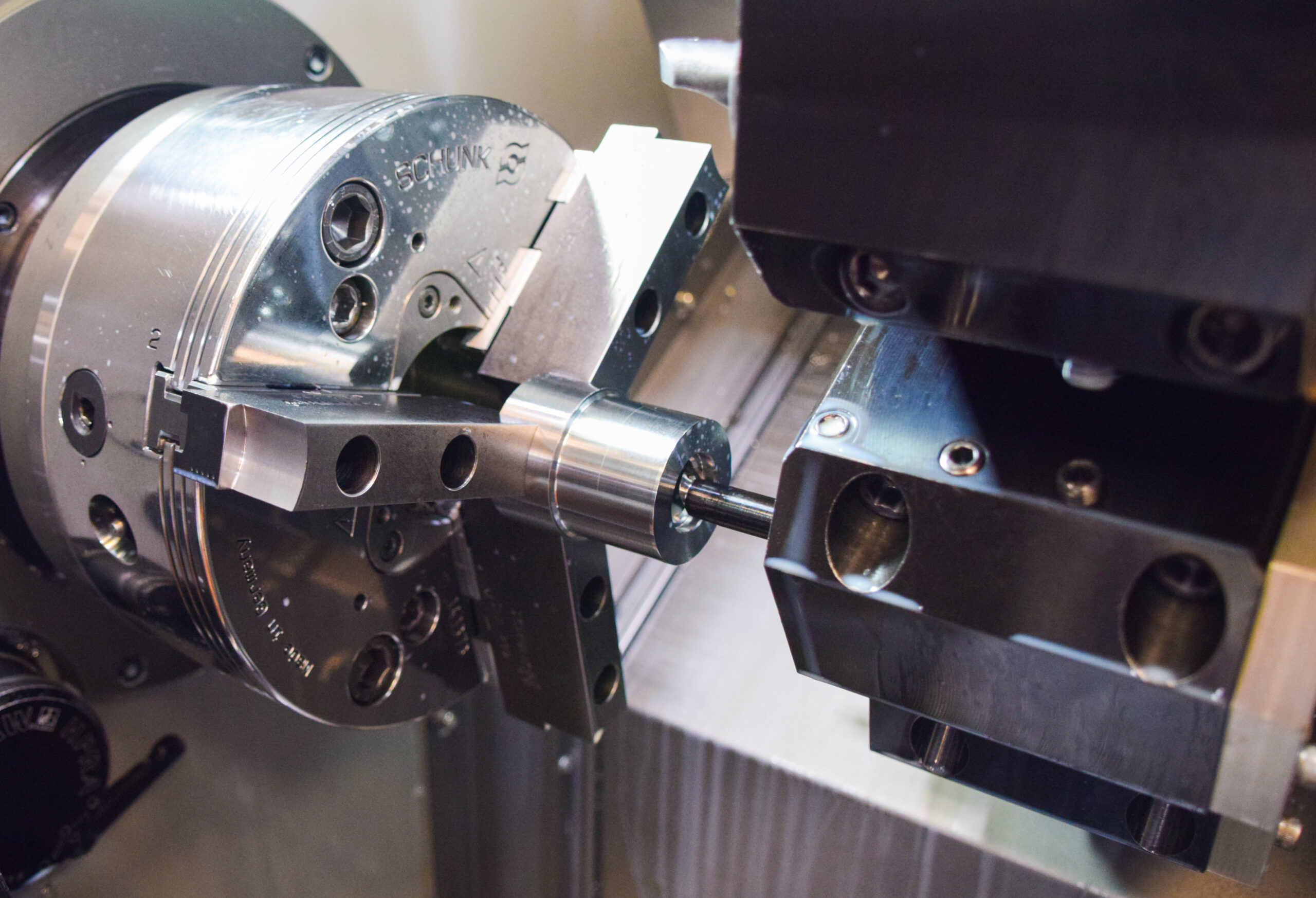

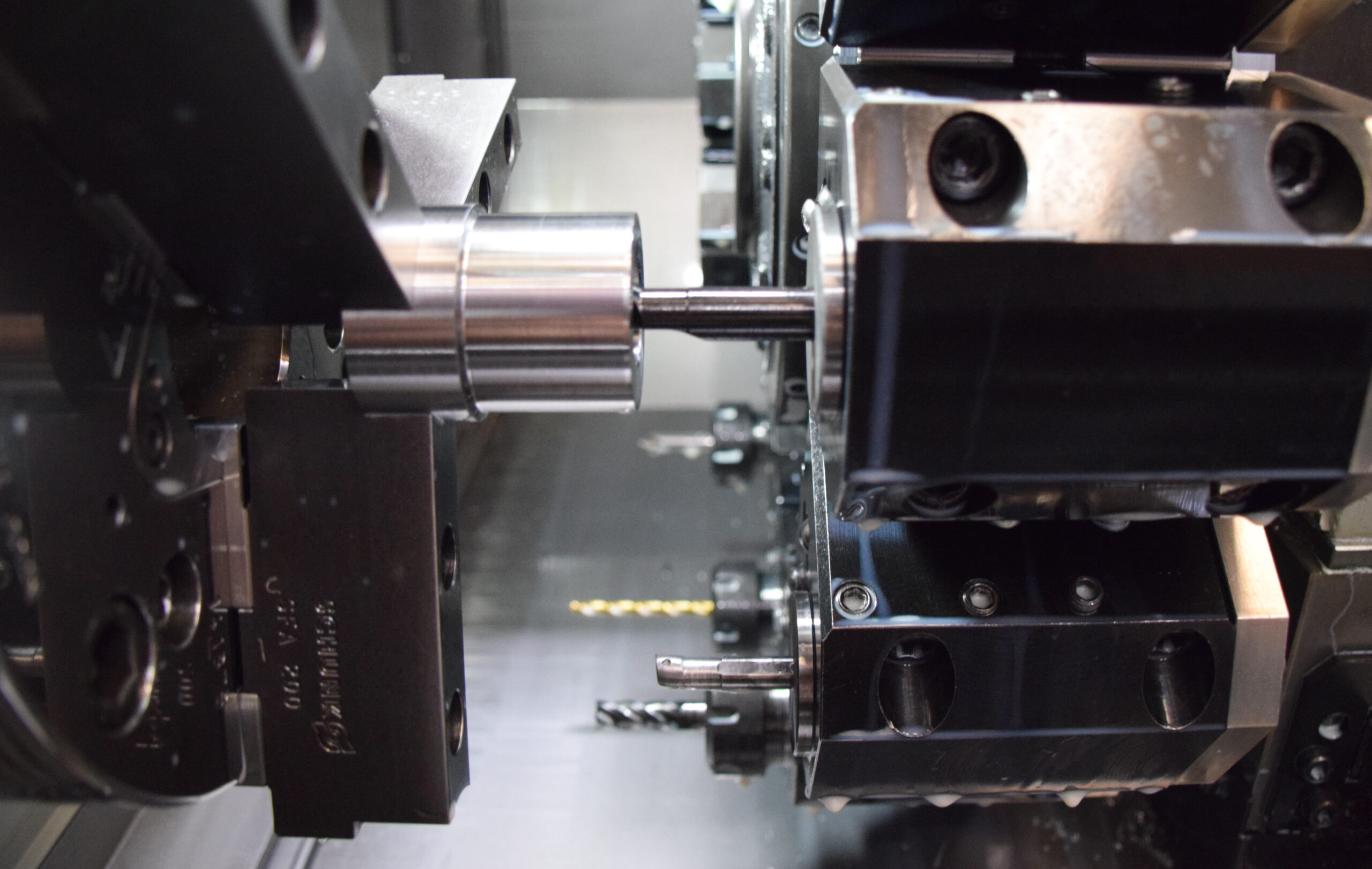

CNC Turning

Our CNC turning services deliver high-accuracy cylindrical components, threads, and shafts for a variety of critical industries. With skilled operators and well-documented setups, we ensure repeatability even on high-mix, low-volume orders.

predictive machines

Fusce dui est ultricies nec ultricies acd porttitor quis tellus ned.

certified factory

Fusce dui est ultricies nec ultricies acd porttitor quis tellus ned.

CNC machining related FAQ’s

We routinely machine to tight tolerances based on customer specifications and part complexity. Typical tolerances range from ±0.005mm to ±0.015mm, depending on the material and geometry. Tolerance capabilities will be confirmed during the technical review, before a quote is produced.

We primarily serve the automotive testing, aerospace, defence, power generation, as well as various OEMs. Our AS9100 certification makes us a trusted partner for products with strict quality and traceability requirements.

We have extensive experience machining a wide range of materials, including:

- Aluminium

- Stainless steel

- Tool steel

- Titanium and Inconel

- Brass and copper

- Engineering plastics

If you have a specific material in mind, just ask—we can likely machine it.

We do not work with carbon fibre or wood / timber.

Our core focus is batch work, and production. Our systems and processes are developed around being able to supply consistent and reliable parts with high-quality standards.

That being said, some customers need a verification batch or initial design before they go into production, we can help with this too.